Plastic injection molding services play a vital role in modern manufacturing, providing companies with a reliable and efficient way to produce high-quality plastic components. These services involve injecting molten plastic into a mold to create precise and complex shapes with consistent results. The method is highly scalable, making it ideal for mass production across various industries, including automotive, medical, electronics, and consumer goods. Businesses looking to achieve tight tolerances and smooth finishes often turn to plastic injection molding services to meet their product requirements.

As product designs become more intricate and demand for plastic parts grows, choosing the right plastic injection molding services becomes even more essential. A professional and experienced molding provider ensures that every aspect of production—from mold design to material selection and final quality checks—is optimized for performance and durability. Without reliable services, businesses risk defects, delays, and higher costs. Therefore, understanding the fundamentals and benefits of plastic injection molding services is the first step toward successful product manufacturing.

Key Factors to Consider When Selecting a Molding Provider

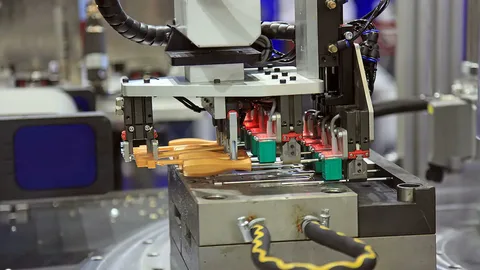

When evaluating plastic injection molding services, one of the primary factors to consider is the provider’s technical capabilities. This includes their ability to handle complex mold designs, produce consistent quality parts, and work with a variety of thermoplastics. A company equipped with modern, high-precision machinery and experienced technicians can deliver superior results with fewer errors. Additionally, having in-house mold-making and prototyping services can significantly reduce development time and ensure alignment between design and production.

Another critical aspect is the molding provider’s quality assurance processes. Reputable plastic injection molding services maintain stringent quality control systems, such as ISO certifications, regular inspections, and testing protocols to ensure every part meets industry standards. Businesses should also look into the supplier’s track record and ask for case studies or client testimonials. This background check helps confirm whether the company is capable of meeting your specific needs, timelines, and budget constraints without compromising on product quality.

The Role of Material Selection in Quality Production

Material selection is a fundamental element in achieving quality outcomes with plastic injection molding services. The type of plastic used directly impacts the functionality, durability, and appearance of the final product. Different resins offer unique properties, such as resistance to heat, chemicals, and impact, which are crucial depending on the application. For instance, ABS may be ideal for electronic housings, while medical-grade polycarbonate may be better suited for healthcare devices. Collaborating with a knowledgeable molding partner ensures the right material is chosen to meet performance and compliance requirements.

Beyond performance, cost efficiency also hinges on selecting the proper material. High-performance plastics often come with a higher price tag, but using them in the wrong context could lead to unnecessary expenses. On the other hand, opting for a cheaper resin that doesn’t meet design specifications can result in product failure. Top-tier plastic injection molding services provide material consultation as part of their offering, helping clients strike the right balance between quality and cost while also factoring in aspects like recyclability and regulatory compliance.

Comparing Domestic and Overseas Plastic Injection Molding Services

Choosing between domestic and overseas plastic injection molding services requires careful analysis of various trade-offs. Domestic providers often offer advantages such as better communication, faster turnaround times, and greater oversight throughout the production process. Having a local supplier means easier access for audits, rapid prototyping, and smoother logistics. These benefits can lead to improved quality control and stronger supplier relationships, especially for businesses with intricate production needs or tight deadlines.

On the flip side, overseas plastic injection molding services—particularly in regions like Asia—can offer significantly lower production costs. This cost advantage is particularly appealing for high-volume manufacturing projects. However, businesses must be cautious about potential challenges, including time zone differences, shipping delays, customs issues, and inconsistent quality standards. While many overseas providers have evolved to offer world-class capabilities, due diligence is crucial. A thorough vetting process, clear contractual terms, and periodic quality audits can help mitigate risks and ensure dependable partnerships.

Building Long-Term Partnerships with Molding Experts

Developing a long-term relationship with a reliable provider of plastic injection molding services can offer numerous advantages beyond cost savings. Consistent collaboration fosters mutual understanding, enabling your molding partner to better anticipate your business needs and innovate alongside your team. Such partnerships often lead to smoother production cycles, quicker turnaround times for design changes, and access to shared expertise that can improve product functionality and manufacturing efficiency.

In addition, long-term molding partners are more likely to invest in your success by providing continuous support, dedicated project managers, and scalable solutions as your business grows. They may also offer value-added services like inventory management, secondary operations, and design for manufacturability (DFM) consultations. These benefits are hard to quantify but essential for businesses aiming for sustainable growth. By selecting plastic injection molding services that prioritize client relationships and long-term value, companies can secure a competitive edge in today’s fast-paced manufacturing landscape.