High-Density Polyethylene (HDPE) sheets are an innovative material used in a wide range of industries, offering exceptional durability, flexibility, and cost-effectiveness. These versatile sheets are known for their remarkable resistance to chemicals, impact, and weathering, making them a popular choice in construction, packaging, marine applications, and beyond.

In this article, we’ll dive deep into the characteristics, benefits, and applications of HDPE sheets, exploring why they’ve become an indispensable Pulkit Plastic Products material in today’s world. Additionally, we’ll answer frequently asked questions to help you better understand their potential uses.

What Are HDPE Sheets?

HDPE sheets are flat sheets made from High-Density Polyethylene, a thermoplastic polymer known for its strength-to-density ratio. The sheets are lightweight yet extremely robust, providing excellent resistance to moisture, chemicals, and abrasion.

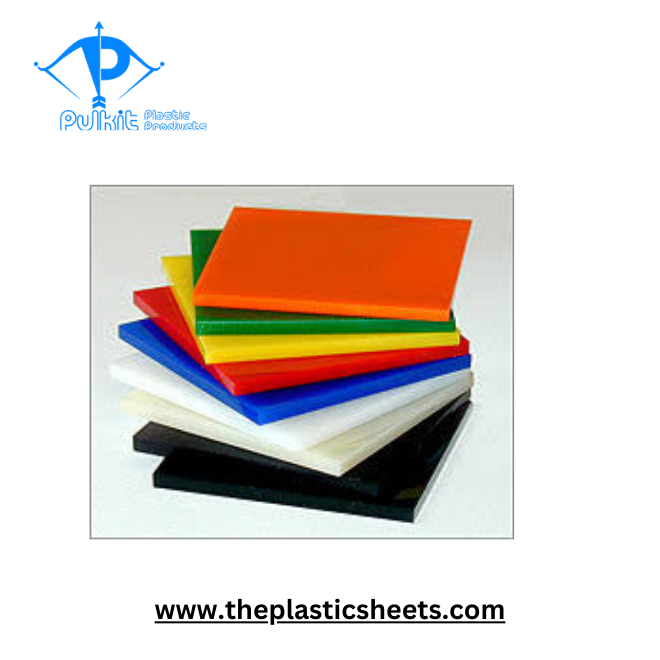

Available in a variety of thicknesses, colors, and finishes, HDPE sheets are highly adaptable to specific needs. They are commonly used in industries such as construction, agriculture, marine, and manufacturing, where long-lasting and low-maintenance materials are essential.

Key Features of HDPE Sheets

1. Exceptional Durability

HDPE sheets can withstand harsh conditions, including extreme temperatures, heavy impact, and constant wear and tear.

2. Lightweight and Flexible

Despite their strength, HDPE sheets are lightweight, making them easy to transport and install in various applications.

3. Chemical and Moisture Resistance

These sheets resist water, chemicals, and UV rays, ensuring long-term performance in challenging environments.

4. Eco-Friendly

HDPE sheets are recyclable and contribute to sustainable practices in manufacturing and construction.

5. Cost-Effective

Their durability and low maintenance requirements make HDPE sheets a cost-effective solution compared to alternative materials.

Applications of HDPE Sheets

HDPE sheets have a wide range of applications due to their versatility and durability:

1. Construction

- Flooring and Wall Panels: HDPE sheets are used as protective layers in buildings, especially in areas exposed to moisture or impact.

- Pipes and Fittings: They are widely used in water and gas distribution systems.

2. Packaging

- Food-Grade Containers: HDPE Sheets price are used to create food-safe packaging due to their non-toxic and moisture-resistant properties.

- Industrial Packaging: Durable sheets are utilized for shipping containers, crates, and pallets.

3. Agriculture

- Greenhouse Linings: HDPE sheets provide insulation and moisture resistance for greenhouses.

- Irrigation Systems: Their chemical resistance makes them ideal for irrigation components.

4. Marine Applications

- Dock Fenders: HDPE sheets protect docks and boats from impact damage.

- Water Tanks: Used to fabricate water storage tanks due to their impermeability and durability.

5. Signage and Displays

- Outdoor Signage: HDPE sheets resist fading and weathering, making them ideal for outdoor signs.

- Exhibition Displays: Lightweight and customizable, they are frequently used in exhibitions and trade shows.

Benefits of Using HDPE Sheets

1. Long Lifespan

HDPE sheets are built to last, providing years of reliable performance in various environments.

2. Easy Maintenance

They are easy to clean and require minimal maintenance, even in outdoor or industrial settings.

3. High Versatility

HDPE sheets can be molded, cut, and shaped to meet specific needs, making them suitable for countless applications.

4. Enhanced Safety

Their non-toxic and FDA-approved variants are safe for food and beverage applications.

5. Aesthetic Options

Available in multiple colors and finishes, High density polyethylene sheet price can enhance the visual appeal of projects.

How to Select the Right HDPE Sheets for Your Project

1. Thickness

- Thin sheets (1–3 mm): Suitable for lightweight applications like packaging or signage.

- Medium thickness (4–10 mm): Ideal for construction and agricultural uses.

- Thick sheets (10+ mm): Best for heavy-duty applications, such as marine or industrial projects.

2. Surface Finish

- Smooth: For easy cleaning and aesthetic appeal.

- Textured: For anti-slip surfaces and outdoor use.

3. UV Resistance

For outdoor applications, ensure the HDPE sheets are UV-stabilized to prevent degradation from sunlight.

4. Color and Customization

Select colors and finishes that match the functional and aesthetic requirements of your project.

5. Grade

- Food-grade: For applications in food processing or packaging.

- Industrial-grade: For heavy-duty applications involving chemicals or impact.

Installation Tips for HDPE Sheets

- Prepare the Surface:

Ensure the installation area is clean, level, and free of debris. - Cut to Size:

Use specialized cutting tools for HDPE sheets to achieve precise dimensions. - Secure with Fasteners:

Use screws, bolts, or adhesives to attach the sheets securely to the structure. - Seal Edges if Necessary:

For applications like water tanks, seal the edges to prevent leaks or contamination. - Inspect Regularly:

Periodically check for wear and tear, especially in heavy-duty applications.

Future Trends in HDPE Sheets

1. Advanced Composites

New formulations are combining HDPE with other materials to enhance strength, flexibility, and thermal properties.

2. Sustainable Production

The manufacturing of HDPE sheets using recycled materials is gaining traction, reducing waste and environmental impact.

3. Smart Materials

Innovations may include HDPE sheets with embedded sensors for monitoring environmental conditions in real time.

4. Expanded Applications

As technology advances, HDPE sheets will find new uses in industries like healthcare, aerospace, and renewable energy.

Case Studies: HDPE Sheets in Action

1. Water Management in Agriculture

A farming cooperative in California installed HDPE sheets as liners for irrigation channels, significantly reducing water loss and improving crop yields.

2. Dock Protection in Canada

A marina in British Columbia used HDPE sheets for dock fenders, enhancing durability and protecting boats from impact damage.

3. Industrial Packaging in Germany

A logistics company in Germany adopted Low density polyethylene price in india for custom crates, ensuring safe and efficient transport of heavy machinery.

Conclusion

HDPE sheets are a versatile and reliable material that excels across various industries. Their durability, eco-friendliness, and adaptability make them a preferred choice for applications ranging from construction and agriculture to marine and packaging.

By understanding their features, applications, and proper usage, you can harness the full potential of HDPE sheets for your projects. Whether you need a durable flooring solution, protective packaging, or a weather-resistant material, HDPE sheets provide unmatched performance and value.

Frequently Asked Questions (FAQs)

1. What is the lifespan of HDPE sheets?

HDPE sheets can last 20–50 years or more, depending on environmental conditions and the specific application. Their resistance to wear and tear ensures longevity in most settings.

2. Are HDPE sheets food-safe?

Yes, food-grade HDPE sheets are FDA-approved and non-toxic, making them safe for use in food packaging and processing.

3. Can HDPE sheets be recycled?

Yes, HDPE sheets are fully recyclable, aligning with sustainable practices and reducing environmental impact.

4. How do I cut HDPE sheets?

You can cut HDPE sheets using standard tools like circular saws or jigsaws with carbide-tipped blades. For precise cuts, consider using CNC machines.