Sheet metal brackets are integral components in aerospace engineering, serving as fundamental elements in aircraft and spacecraft assembly.

In this article, we will explore the critical significance of sheet metal brackets within aerospace applications, emphasising their pivotal role in ensuring structural integrity and functionality. Additionally, we will delve into the importance of aviation welding services in the fabrication and assembly of these brackets, highlighting the expertise and precision required in their manufacturing process.

By understanding the essential role of sheet metal brackets and the crucial contribution of aviation welding services, we gain insight into the intricate nature of aerospace engineering. Through this exploration, we aim to underscore the significance of these components and the meticulous craftsmanship involved in their production, ultimately showcasing their indispensable role in the construction and operation of aerospace vehicles.

Key Components in Aerospace Structures

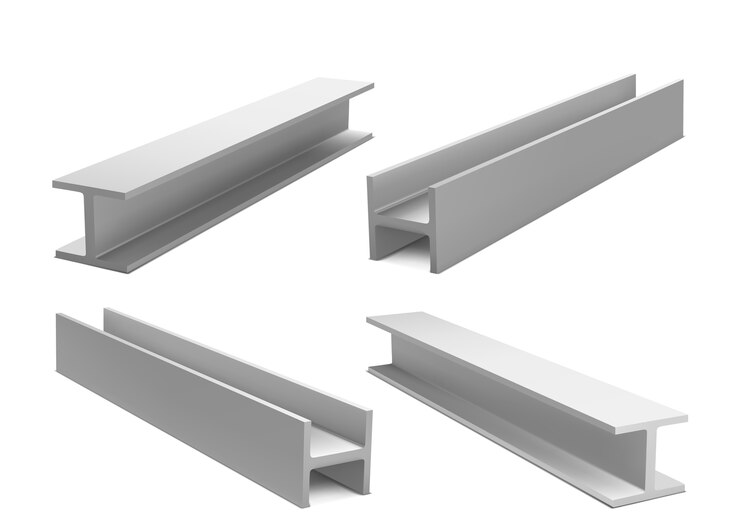

Sheet metal brackets are structural components fabricated from thin metal sheets such as aluminium, titanium, or stainless steel. They provide support, reinforcement, and attachment points in various aerospace structures, including airframes, wings, fuselages, and propulsion systems. These brackets are designed to withstand high levels of stress, vibration, and temperature fluctuations encountered during flight, ensuring the structural integrity and safety of aircraft and spacecraft.

The Role of Aviation Welding Services

Aviation welding services play a vital role in fabricating and assembling sheet metal brackets for aerospace applications. Skilled welders use advanced welding techniques such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and resistance welding to join sheet metal components with precision and reliability. These welding processes ensure the formation of strong and durable welds, capable of withstanding the extreme conditions experienced in aerospace environments.

Benefits of Sheet Metal Brackets in Aerospace Engineering

- Lightweight and Durable Construction: Sheet metal brackets offer a cost-effective solution for aerospace structures due to their lightweight yet durable construction. They help minimise overall weight while providing sufficient strength and rigidity. It provides support for critical aircraft and spacecraft components.

- Versatility and Customisation: Sheet metal brackets can be fabricated in various shapes, sizes, and configurations to suit specific design requirements in aerospace engineering. This versatility allows engineers to maximise the performance and functionality of aerospace systems while minimising material waste and manufacturing costs.

- Enhanced Structural Integrity: Sheet metal brackets play a vital role in enhancing the structural integrity of aerospace structures by providing reinforcement and attachment points for critical components. They help distribute loads evenly, reduce stress concentrations, and improve overall stability and performance during flight operations.

- Cost-Effective Manufacturing: The fabrication of sheet metal brackets for aerospace applications is a cost-effective process compared to alternative manufacturing methods. Sheet metal forming techniques such as stamping, bending, and laser cutting allow for high-volume production at relatively low costs. It eventually makes them an economical choice for aerospace manufacturers.

- Compatibility with Advanced Materials: Sheet metal brackets are compatible with a wide range of advanced materials used in aerospace engineering, including composites and hybrid materials. This compatibility enables seamless integration with modern aircraft and spacecraft designs, facilitating innovation and advancements in aerospace technology.

Conclusion

Sheet metal brackets are vital in aerospace engineering, providing essential support, reinforcement, and attachment points in aircraft and spacecraft structures. Fabricated with precision and expertise through aviation welding services, these brackets offer lightweight, durable, and cost-effective solutions for aerospace manufacturers.

By understanding the importance of sheet metal brackets and their role in enhancing structural integrity and performance, aerospace engineers can drive innovation and excellence in aerospace engineering.